Company Name: PaperSeal

Country: Lithuania, Latvia, Estonia

Industry: Packaging and Containers Retail

Company size: 11-50 employees

VentorTech solutions: Odoo Direct Print PRO, Ventor, Odoo consulting

Goal: Implement mobile terminals for all warehouse operations and optimize “Quote to Cash” workflow

About the company

PaperSeal is a shipping supply and decorative packaging retail company that offers online and in-store shopping, operating across the Baltic States: Lithuania, Latvia, and Estonia.

They sell various packaging and finishing materials, such as cardboard boxes, transport boxes, tapes, envelopes, gift boxes, bags, and more.

Business workflow

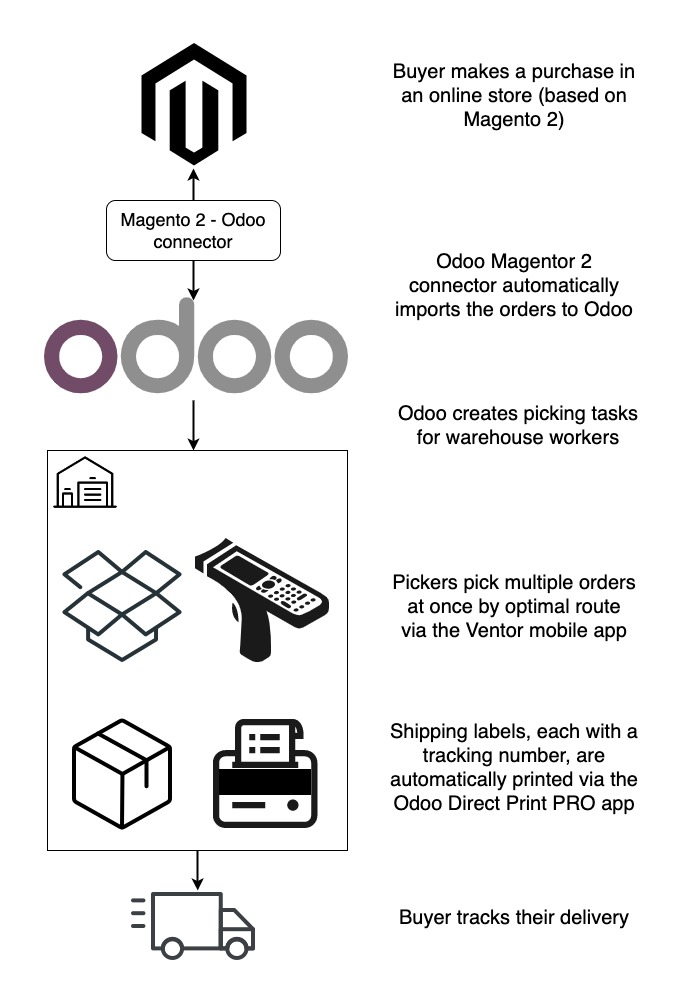

Selling goods offline and online (Magento 2 store on the backend), orders are automatically imported to Odoo ERP via an Odoo Magento 2 connector. Then pickers pick the delivery order items using mobile terminals, pack them, and print shipping labels. After that, obtained tracking numbers are exported to Magento and visible in the buyer’s personal account.

Problems

Working in the market since 2013 and constantly growing, PaperSeal faced a typical bottleneck of business scaling: efficiency in warehouse operations.

“Most of the scaling problems that rose before us were related to the inventory. As the product line and number of orders kept on growing, we had a difficult time keeping track of the product quantities, locations, and order processing speed.”

They figured out three main problems:

- Lack of a warehouse management system (WMS)

“We used mobile tablets to open orders on our e-shop and pick directly from it. Using tablets was inconvenient because they were too big to carry around all the time. Also, it was difficult to keep track of who was picking what, especially when we had more pickers. We quickly noticed that with every new worker in the warehouse, we gained less and less efficiency.” - Lack of smart picking routes.

Having a warehouse (up to 3000 m2) with 4–9 shelves, pickers often had to return to already visited zones while picking one order, and then again when picking another order, and so on. - Lack of good Odoo consultants.

Local Odoo partners had no domain expertise in logistics, and this complicated the understanding of specific business processes.

Goals

They were sure from the start that they wanted to use Odoo, since it still had some similarities to their existing OpenERP.

The project manager of PaperSeal asked us to help them to optimize daily inventory operations and boost warehouse efficiency.

He had three main goals to optimize warehouse:

- Integrate mobile terminals for all daily operations.

- Create a warehouse map and optimize picking routes.

- Implement product barcodes via Odoo.

Ventor PRO: Odoo barcode app

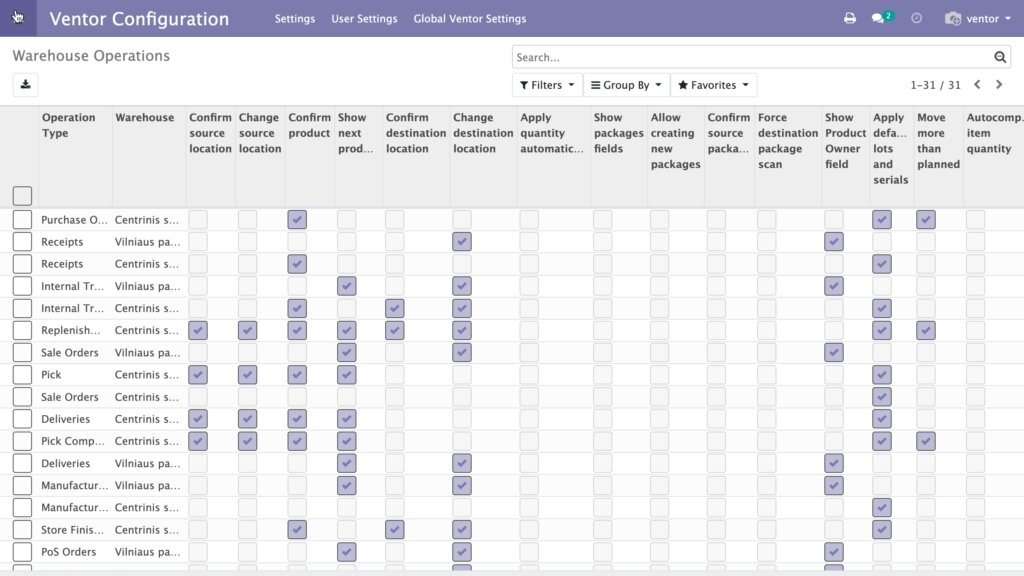

The next step was the implementation of mobile terminals and the Ventor app in daily processes. While making Odoo changes, they have been testing Ventor along the way. They had to try different mobile terminal models that are best suited for different Odoo operation types: receipts, internal transfers, order picking, and packing.

“We like the flexibility of the Ventor app that lets us use it on any Android device. For example, for our pickers, we chose wrist mounted terminals along with finger scanners. It was very important for us that the picker would have both hands free not only for product picking, but for the ability to safely operate the order picker as well.”

Odoo warehouse map

For all warehouses, all zones and locations were assigned related names and barcodes according to best practices from warehouse experts. All warehouse locations were exported to Odoo.

Odoo picking routing optimization

Based on the warehouse map, an optimal picking route was built and implemented in Odoo via the picking and reservation strategy app.

“The Picking and Reservation Strategy module helped us to create the custom picking route that is optimized specifically how we want it”

Cluster picking in Odoo

“Cluster Picking lets us pick and sort multiple orders at the same time. Now 4 pickers can easily achieve the same picking speed as 8 pickers used to before.”

Having many orders daily, PaperSeal uses the cluster picking option in Ventor to pick multiple orders at the same time.

Using cluster picking with Ventor, the customer has the following benefits:

- One picker picks many Odoo orders at once.

- The orders are sorted on the go; no need to spend time on packing.

- Pickers minimize walking time by following optimal routes.

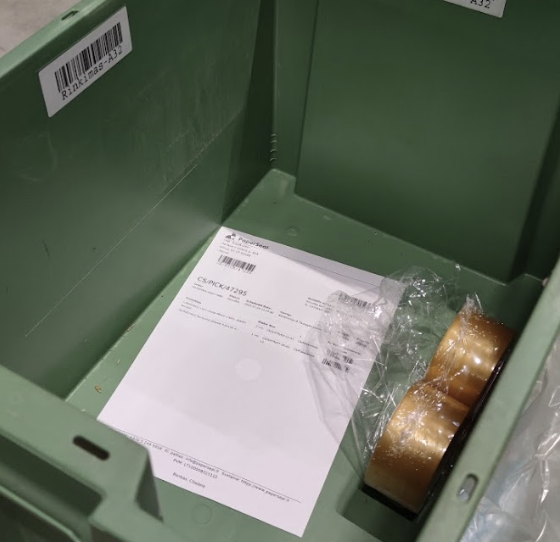

“We use Cluster Picking for orders and sort them into picking boxes. These boxes have assigned names, which really are child locations of the packing zone. On packing, we used to scan a box instead of an operation barcode, and Ventor instantly finds us the related picking assigned to that box.”

Odoo Direct Print PRO

Instead of downloading from Odoo any PDF report like picking operation or ZPL shipping labels and manually sending them to a related printer, PaperSeal uses the Odoo Direct Print PRO app. Automatic print scenarios allow instant printing of any document from Odoo.

For example, when a packer validates an order in Ventor, they get a printed shipping label from a carrier in seconds.

“Also, we use Odoo Direct Print PRO for easy printing of delivery slips as well as printing Odoo product barcodes directly from the mobile terminal.”

Odoo product barcodes

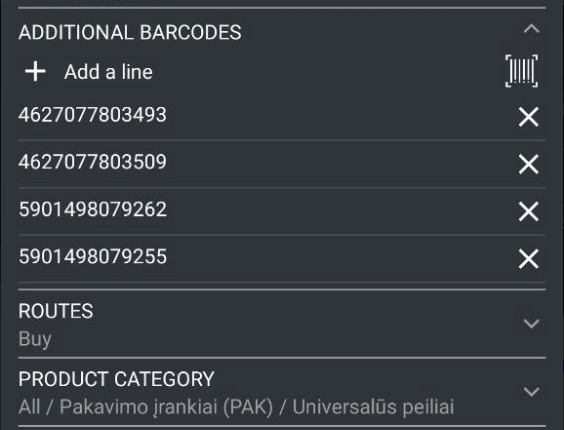

The customer never had product barcodes in Odoo. They scanned all product barcodes into Odoo from scratch using the Quick Info menu in Ventor. Some products have more than one barcode, so they use the Product Multiple Barcodes module for those instances.

Ventor PRO customizations

It’s not a secret that every business is unique and often requires developing Odoo customizations for a specific customer’s workflow. The same was with the Ventor PRO: Odoo barcode scanning app.

For PaperSeal, we customized the packing workflow in the app and improved access rights settings in the Ventor Base app (Odoo module that extends Ventor’s functionality) to achieve a more flexible and customer-ready solution.

The customer can change Ventor settings from Odoo (e.g., restrict some operations for a particular user, limit locations or warehouses, allow working on inventory adjustments, etc.)

An important point is that Ventor PRO is easy to customize, and moreover, migrating to new Odoo versions is easy. It’s almost impossible to customize the Odoo barcode app (available only for Enterprise users), and entirely impossible to migrate this custom code in the future. With Ventor PRO, you can forget about migration issues.

Odoo consultations

As the customer had an onsite Odoo development team, most of development was implemented by this team. VentorTech, and specifically Ventor CBDO Vitaly Eremeev, was engaged as a consultant for the Odoo warehouse part. Having great expertise in Odoo Inventory, we quickly figured out the core of any constraints and suggested optimal solutions.

The collaboration was a win-win. PaperSeal’s Project Manager provided us with much useful feedback regarding Ventor. We improved the serial numbers workflows, batch and cluster picking, the app’s UX along with translating the app into Lithuanian, and much more.

It’s always nice to work with such customers 🙂

Results

PaperSeal boosted the efficiency of their warehouses. All daily operations were optimized using barcode scanners and printers connected to Odoo.

Receiving goods and creating serial numbers for new quants, internal transfers to warehouse locations and offline stores, inventory adjustments, picking by fastest route, packing with instant printing of shipping labels retrieved from carriers – now all this allows processing 2 times more orders per day with the same staff.

- All that let us improve our order processing effectiveness by 100%.

- We reduced our costs significantly.

- We reduced our margin of error by 5x and improved customer satisfaction overall.

- We have been using the Ventor app for 18 months now for every transfer in our warehouse.

Of course, it didn’t all happen in one day. Odoo optimization is a never ending process, and we continue to update our system and implement the newest features of the apps. Some of them are big. Some of them are small, but still, if you make ten small improvements, it adds up.

written by

Vasily Puntus

Head of Marketing at VentorTech