Why picking speed matters

Warehouse managers know how crucial the picking speed is for the bottom line.

Higher revenue

the more goods you can move through your warehouse, the more revenue you can generate in the result.

Lower stock management costs

enabling fast movement of goods in the warehouse, you can reduce the costs of stock management per product.

Improved customer experience

customers receive their products faster, which increases their satisfaction with your service and makes them return for new purchases.

Waves picking > Batch picking > Cluster picking

One of the most efficient ways to increase picking speed is a multi-orders picking process. There is a variety of picking methods to suit different workflows. A few pickers can work on one order, or one picker can pick many orders in one pass. Orders can be picked by a certain delivery date or during shifts and so on. Let’s review three classical approaches (note, all of them require using barcode scanners).

Combining orders by some general conditions. Typically, orders are picked one after the other without route optimization. Waves allow putting orders according to required parameters.

Minimize walking to the same items from different orders to fill all of them. This approach is useful in case if you have the same items in all orders you have added to the batch.

Each order gets a dedicated box(es) that is usually put on a cart to keep items from different orders separated while picking. This approach allows the picker to avoid walking to the same locations and allows for all items to be sorted in boxes by the end of a picking route.

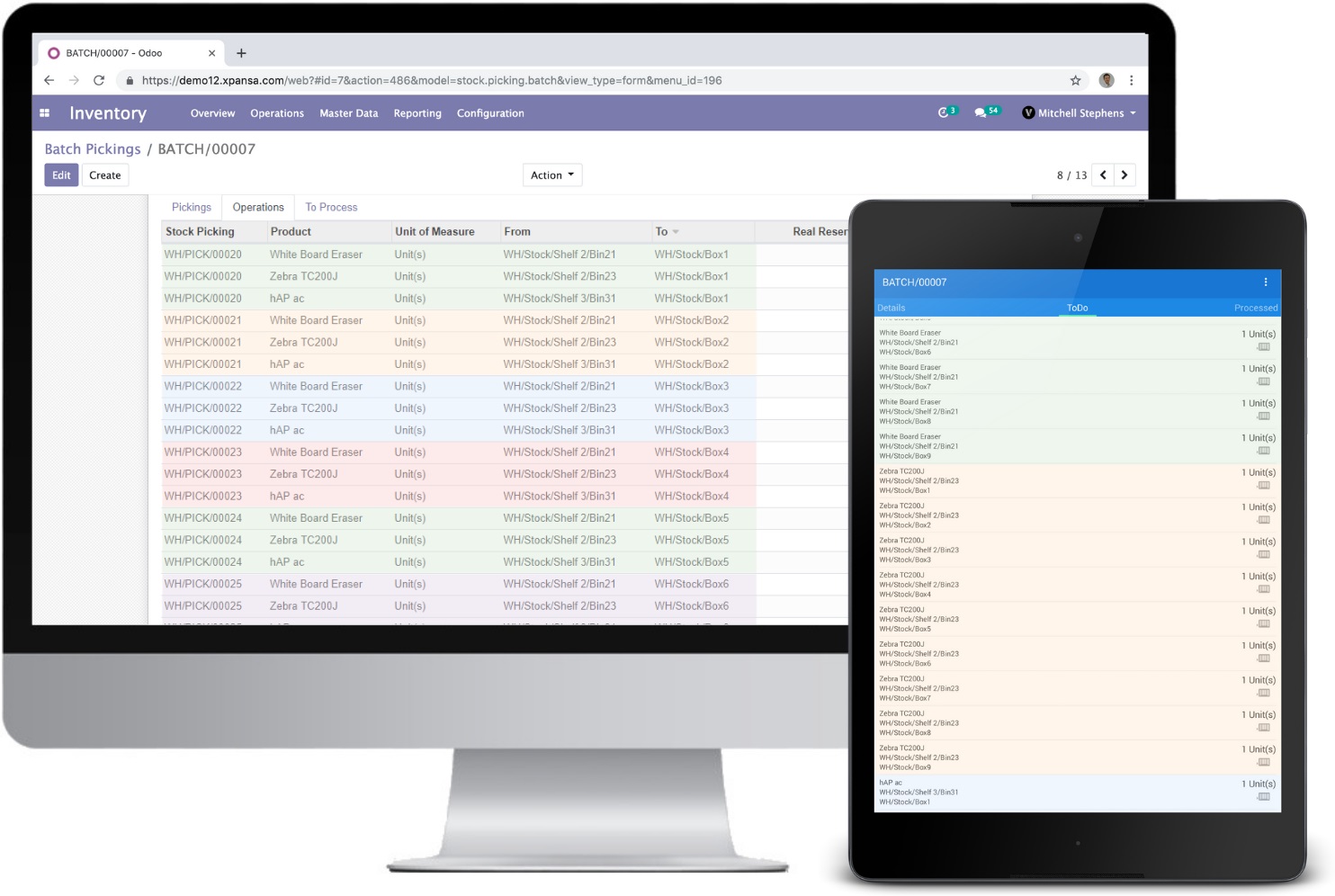

Now let’s look at these three ways to pick multiple items in more detail. For an example, we will use the popular open-source ERP system, Odoo, and a mobile app-assistant, Ventor, that can be installed on mobile computers like Zebra MC33, TC25, and so on.

Waves picking

This method is used to combine orders into small sets called “waves” based on some shared parameters. Typically, orders are picked one by one without route optimization.

Orders can be grouped according to

- Delivery date

- Picking zones in the warehouse

- Type of orders

- Customer location

- Frequency of orders

The warehouse manager combines orders together, or WMS/ERP does the same automatically. Waves can be assigned to related pickers, and they collect items according to routes suggested in the application on the mobile computer.

There are some popular picking approaches based on waves. Let’s look at them.

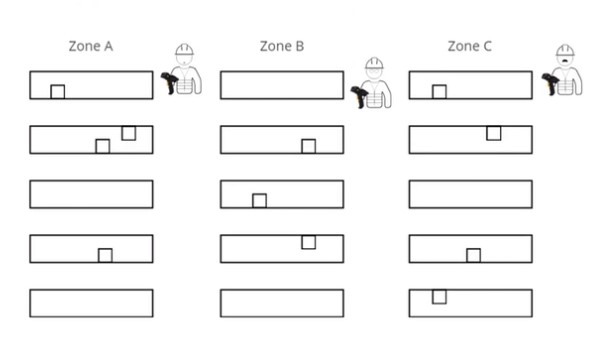

Picking based on picking zones

For example, waves picking allows picking orders as one long order split on three “waves,” based on warehouse zones. This way, three pickers can collect orders in parallel in three different zones.

Based on the delivery date

Imagine you have 20 orders from your website

- 10 need to be delivered tomorrow

- 8 need to be delivered next week

- 2 need to be delivered next month

We can create three “waves” for each group of orders based on delivery date. Ten merged orders will be collected by one picker, and then they will be split by orders and sent on the same date.

Waves picking is good for

- Medium and large warehouses (distribution centers)

- Warehouses with medium/large numbers of SKUs

- Orders can be filtered by some standard parameters

- The products have a wide range of sizes

Batch picking

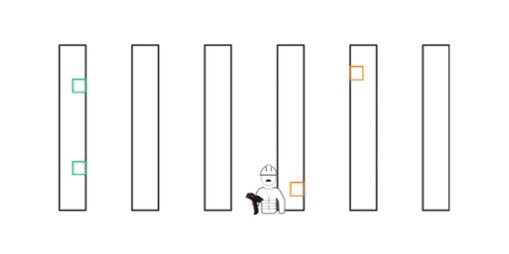

Groups of sales orders picked at the same time is called batch picking. This method is usually applied to minimize repeat visits to the same stocked items in the same locations.

Imagine that you have 20 orders you need to pick. Each order contains 3–6 lines. There are some of the same items repeated in different orders. It’s more quickly to pick all items from 20 orders as 1 big order at once by 1 picker only. So, batch picking allows you to go through locations once and collect all needed items for all 20 sales orders.

A warehouse manager simply creates a batch picking order in a WMS (or it is created automatically), and a picker goes through the shelves following the instructions on his mobile computer.

Cluster picking

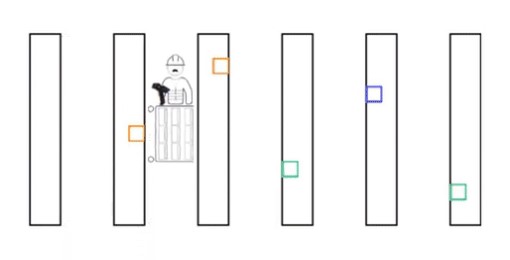

The cluster picking method involves using boxes or baskets and pulling items for each order into an assigned box. This method helps a packer not spend time on sorting items for each order sent to the packing zone.

For example, in the case of batch picking, we need to split items into nine initial sales orders after we pick them, or each time after the pick, we need to go to the packing zone to add the needed quantity of items to the correct box.

If you want to sort items during picking, cluster picking works well. First, you need to assign each basket (e.g., a box or container that is simply another location in the system, such as shelves) to a particular sales order.

Then, your WMS generates new moves from regular items’ places to the needed basket. The picker follows a route showed in an application on his barcode scanning device. The app shows the picker what product to pick, where it is located, and in which basket it should be placed. Sorting is working right on the go.

After the picker has completed the cluster picking, items for all orders are picked into separate boxes. This significantly saves time on packing zones, as items are already prepared and sorted.

Batch and cluster pickings options are good for

- Small and medium warehouses

- Warehouses with low/medium numbers of SKUs

- Products should be compact

- Usually involves 1–6 lines per order

- You have dedicated baskets (optional for cluster picking)

Conclusion

Using batch and waves picking allows you to significantly increase the speed of picking goods for your customers. You don’t need to hire additional staff or rent another warehouse to process more orders with the same tools.

Achieving efficient warehouse pick path optimization is crucial for seamless order fulfillment and operational success. With the growing competition in the logistics industry, staying ahead requires implementing cutting-edge methods like “Batch Picking” and “Pick-to-Light.” By optimizing the picking path and adopting advanced technology, such as AI-driven route planning and real-time analytics, warehouses can significantly reduce picking time, enhance staff productivity, and ultimately exceed customer expectations.

At VentorTech, we understand the importance of picking optimization in modern warehouse management. Our comprehensive solutions leverage the latest innovations to help you streamline your picking process, minimize errors, and boost overall efficiency. By focusing on intelligent pick path optimization, your warehouse can gain a competitive edge and thrive in today’s fast-paced market. Let VentorTech be your partner in achieving warehouse excellence and delivering unparalleled customer satisfaction.

written by

Vitaly Eremeev

CBDO at VentorTech